Microcrystalline cellulose is the main excipient used in the industrial manufacture of pellets by extrusion/spheronization, but pellets containing this spheronizing aid do not readily disintegrate and are expensive.

Fridrun Podczeck is professor of pharmaceutics at Sunderland School of Pharmacy, University of Sunderland, UK

Microcrystalline cellulose is the main excipient used in the industrial manufacture of pellets by extrusion/spheronization, but pellets containing this spheronizing aid do not readily disintegrate and are expensive.

Last year, the Royal Pharmaceutical Society of Great Britain held a consultation regarding how the profession should develop during the next 12 years. An analysis of the results has just been published.1 It comes as no surprise to anyone who teaches pharmaceutics at UK pharmacy departments that one popular suggestion was to change the indicative syllabus so that it would focus more on clinical topics as opposed to scientific ones.

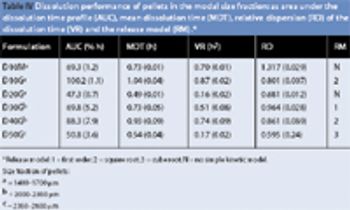

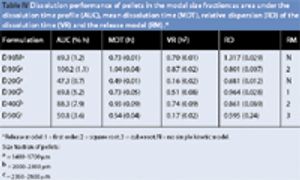

The previous studies on the incorporation of glyceryl monostearate into pellets by extrusion/spheronization has been extended to include a range of grades of this material plus a mixed medium chain partial glyceride and two glycerol esters of hydrogenated natural glycerides as described in this article.

The process of extrusion/spheronization used to produce spherical granules frequently relies on formulations containing microcrystalline cellulose (MCC). This excipient can hold water, even when pressure is applied, and form "pastes" that have suitable rheological properties, which allow both extrusion and subsequent spheronization to produce uniform spherical granules. This article describes a new approach to providing paste systems with appropriate characteristics. This can be achieved by incorporating glyceryl monostearate (GMS) into the formulation. It was found that the inclusion of GMS in formulations provides a useful alternative to MCC as an effective excipient to aid the preparation of spherical granules, allowing the incorporation of drug loads as high as 90%.

Published: July 1st 2008 | Updated:

Published: December 1st 2008 | Updated:

Published: December 1st 2005 | Updated:

Published: October 1st 2004 | Updated: