Policy makers seek to ensure supplies of new therapies and to limit shortages.

Policy makers seek to ensure supplies of new therapies and to limit shortages.

Will moving at “warp speed” to develop a vaccine impact efficacy or safety?

Having a better understanding about compliance will be of benefit when looking for a job or for furthering one’s career, says Siegfried Schmitt, PhD, vice-president, technical, Parexel Consulting.

Industry must never become complacent about the safety of drug products and should seek to continually perform surveillance even if the drug is well-established.

In light of the hype around chloroquine and hydroxychloroquine as potential COVID-19 treatments, it is important to remember that drug repurposing should never be rushed, irrespective of the urgency of the situation.

EMA’s strategy for regulatory science has divided opinion amongst various industry bodies.

Organizations involved in aseptic and sterile processing activities must make an effort to comply with current good manufacturing practices.

Distek’s small-volume conversion kit for its Model 2500 Select bathless dissolution tester uses bathless heating technology and the continuous monitoring and control of the in-vessel temperature to eliminate the water bath in the dissolution tester.

Inline high shear mixers from ROSS are available from 1 through 250 HP to accelerate mixing, emulsification, and homogenization in recirculation and continuous modes.

Tosoh Bioscience introduced the SkillPak 1 mL and 5 mL pre-packed columns for fast method development and resin screening of monoclonal antibodies, antibody constructs, oligonucleotides, proteins, and viruses.

Smart Containers from SCHOTT work to improve reject management and line clearance via a unique identifier to create traceability throughout the manufacturing process.

Equipment and process optimization must be considered for scaling up these developmental technologies to commercial production.

Light obscuration testing is the preferred method of sub-visible particle quantification but is not suitable for every preparation.

Many antibody-drug conjugate therapies are in the pipeline; however, only a handful have been approved. What are the bottlenecks?

Discovery of carcinogenic nitrosamines in three of the world’s most widely prescribed drugs is driving efforts to better detect, control and prevent their generation in APIs and finished drug products.

Experience, communication, collaboration, transparency, planning, and prioritization contribute to success.

A well-defined contamination control program is essential to maintain quality through aseptic manufacture of parenteral drug products.

Bioprocessing advances improve product yield, cut costs, and streamline integration between upstream and downstream processes.

Reformulation strategies can provide drug developers with a head start to achieve promising options that benefit the patient.

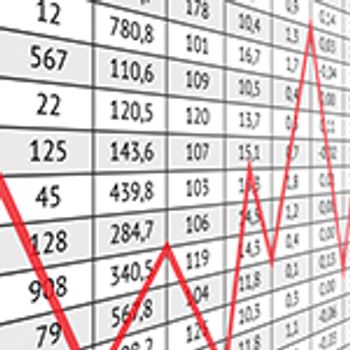

The CuDAL-Excel program, based on Microsoft (MS) Excel, has been developed to calculate the United States Pharmacopeia (USP) passing probability of content uniformity and dissolution tests for both sampling plan 1 and sampling plan 2 scenarios and for both immediate release and extended release requirements. The users can obtain the passing probability by simply entering the input variables, with wide applications for process validation/verification and batch release. As a user-friendly program, CuDAL‑Excel should bring more benefits to the industry practitioners than other existing programs/tools.

Click the title above to open the Pharmaceutical Technology May 2020 issue in an interactive PDF format.