Applying lessons of raw materials’ characterization and supply-chain control from the semiconductor industry allow more rigorous control of the biopharmaceutical manufacturing process.

Applying lessons of raw materials’ characterization and supply-chain control from the semiconductor industry allow more rigorous control of the biopharmaceutical manufacturing process.

Visualization using virtual and mixed reality can aid with biopharma manufacturing facility design and training.

Shim-pack Bio Diol and IEX columns from Shimadzu Scientific Instruments improve the accuracy of the characterization of peptides, oligonucleotides, and other biopharmaceuticals.

BD’s new Intevia 1mL two-step disposable autoinjector, a device that combines an autoinjector and a pre-fillable syringe into one system, has a two-step, push-on-skin activation feature that allows the effective and safe injection of drugs of different viscosities up to 35cP and different fill volumes up to 1mL.

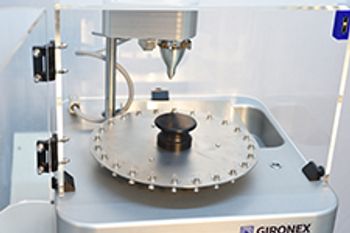

Cube Plus by GiroNEX is an automated precision powder dispensing system for use in manufacturing powder-filled capsules and vials for early phase clinical trials and related drug development studies.

The latest 600-gallon VersaMix Model VM-600 from Ross is qualified for high-speed subsurface powder induction with a proprietary Ross Solids/Liquid Injection Manifold (SLIM).

Nearly four decades after the first diagnosis, the fight to treat HIV/AIDs continues.

The key is to ensure that excipients only interact with APIs via desired mechanisms.

As the UK heads to the polls for an unusual December general election, industry issues manifestos on medicines while Europe rejoices some movement … finally.

Regulators are facing huge challenges on how to deal with the digitalization transformation occurring in the healthcare and pharmaceutical sectors.

Spray drying is a versatile and rapid technique that can provide companies with a suitable and scalable option to improve the solubility and bioavailability of drug products.

As regulatory bodies extend the oversight of E&L testing, companies working with drug products need to make provisions on how to best comply with the evolving expectations.

Communications and planning are crucial to recovering from supply, operations, and facility disruptions.

As equipment evolves and use of PAT increases, DOE is becoming an integral part of upstream bioprocess development.

Click the title above to open the Pharmaceutical Technology December 2019 issue in an interactive PDF format.

Problems in assuring reliable drug quality and supply dampens progress in bringing lifesaving therapies to market.

Investigating deviations of combination products needs to accommodate both the drug and device components, says Susan J. Schniepp, executive vice-president of post-approval pharma and distinguished fellow, Regulatory Compliance Associates.

This article discusses reduced sampling and testing of starting materials or components. Different strategies are presented to reduce the workload at the steps from sampling to release. Viewpoints from the different pharmacopoeias and regulatory authorities, as well as selected literature, are reviewed.