Manufacturing, Solid and Semi-Solid Dosage Drugs

Latest News

Latest Videos

More News

As part of a range of sustainable products and services that SGD Pharma plans to showcase at CPHI Milan, the company will introduce its siliconized molded glass vials.

Charles Ross & Son Company has introduced the ROSS CDA-300 Dual Shaft Mixer, consisting of two agitators and a disperse with an open disc blade.

Technical, regulatory, and personnel considerations characterize pharmaceutical compounding.

Dosage forms are being shaped by numerous factors, with patient-centricity continuing to be an important driver of decisions in development.

Twin-screw granulation process insight is growing as researchers employ new analytical technologies and investigate new ways to use the equipment.

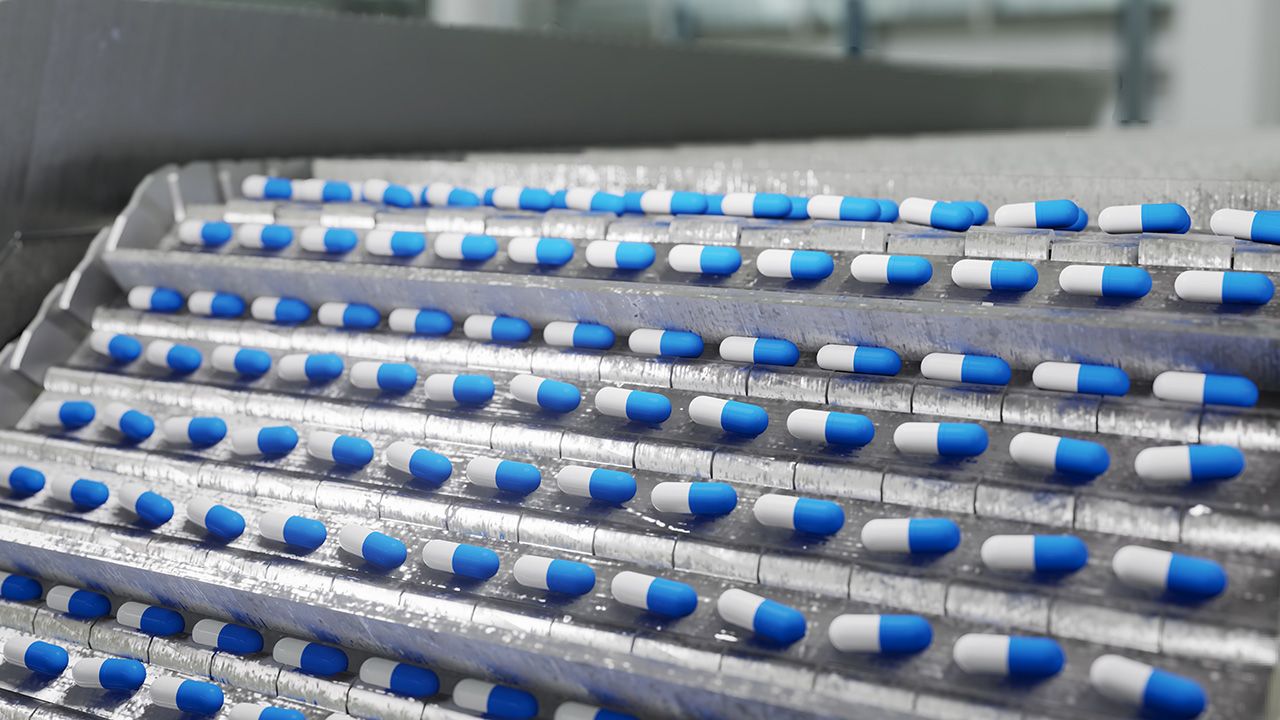

Current good manufacturing practices for oral solid dosage forms protect the product from contamination and potential errors.

Felicity Thomas, European/Senior Editor, Pharm Tech Group, and Andy Dumelow, Head of Technical Sales, I Holland, chat about tablet tooling maintenance in this brief podcast.

A good understanding of tablet tooling and how to properly maintain these key parts will maximize lifespan of tools.

Manufacturers must consider key components of manufacturing solid versus semi-solid drugs to create a successful end product.

The state of oral solid dose manufacturing is influenced by new approaches, novel technologies, and the structural evolution of the raw materials market.

This article is focused on introducing a control chart technique using relative standard deviation (RSD) statistics (i.e., RSD chart); in other words, a coefficient of variation chart for continued process verification.

Catalent has announced a $175 million project to expand its manufacturing facility for large scale oral dose forms at its Winchester, Ky, site.

Innovations address sustainability, serialization, and supply-chain issues.

The latest manufacturing technologies are essential for helping pharmaceutical formulators meet up-and-coming trends in OSD treatments.

By following some fundamental steps, manufacturers can optimize their tablet tooling maintenance and resulting productivity.

With the majority of large pharmaceutical manufacturers aiming for carbon neutrality by 2030, reusable packaging remains a largely untapped approach in achieving measurable ESG gains.

In this episode of the Drug Solutions Podcast, Jennifer Markarian, manufacturing reporter, talks about continuous manufacturing of oral solid-dosage drugs with Lawrence De Belder, executive consultant at Pharmatech Associates, a USP company.

Collaboration and new tools aid efforts to implement new processing technologies for small-molecule drug product manufacturing.

Smart manufacturing transforms management of tablet and capsule equipment and processes.

CDMOs offer expertise and capacity for spray drying.

CordenPharma will build a clinical trial development facility for manufacture of oral solid dosage drug products at its Plankstadt facility near Heidelberg, Germany.

Gernot Warnke, Head of R&D, JRS Pharma, spoke about excipients and how these relate to feeding in batch and continuous manufacturing.

Sharon Nowak, Business Development Manager, Coperion K-Tron USA Food & Pharmaceutical Industries spoke about feeding equipment in solid-dosage drug manufacturing.

Fernando Muzzio, PhD, Distinguished Professor of Chemical and Biochemical Engineering at Rutgers University, spoke about trends in continuous manufacturing of OSD drugs.

Johannes Khinast, PhD, Institute for Process and Particle Engineering in the Research Center Pharmaceutical Engineering (RCPE) at the Graz University of Technology in Austria, spoke about continuous manufacturing of OSD drugs.