Whitepapers

All series

All Whitepapers

Did you know that running costs for a CO2 incubator easily exceed its purchase price over time? Learn how the CellXpert can help you to save money for your lab.

Contamination is associated with experimental repeats and project delays. In this White Paper we discuss the best strategies to prevent contamination in cell culture.

This article surveys punch and die modifications that can address tablet defects and reduce wear, extend tool life, and streamline press operation.

DuraGran® reduces the excipients and/or steps to build beads or granules, and at higher concentrations, spheronization and extrusion steps typically used can be forgoed.

This white paper explores energy strategies aimed at reducing your carbon footprint while simultaneously increasing resiliency, efficiency and profitability

Product variability from biopharmaceutical manufacturing to storage can significantly impact the safety and efficacy of batch-to-batch products during clinical use.

Making an effective vaccine faces obstacles which depend on a complete line-up of pharmaceutical-grade refrigerators and freezers to maintain the necessary conditions.

As biological products are being investigated as treatment modalities, measures to ensure safety and quality from microbiological contamination becomes imperative.

Assuring sample integrity and security in the biopharmaceutical workflow process is important to establishing standards that guarantee proper sample security.

Companies looking to implement a quality management system (QMS) are faced with a dilemma: They can design a custom system from scratch or invest in purpose-built software. Before you decide which kind of QMS is the best fit for your needs, learn the pros and cons of each.

Adaptdose™ allows drug developers to quickly create custom oral delivery systems and reduce time to market by eliminating the need to reformulate after Phase I in many cases.

Accurately identifying analytes that exceed the ICH identification thresholds is critical to a compound’s safety and stability profile in preparation for NDA filing.

Join Eurofins BioPharma Product Testing and Vanrx (now part of Cytiva), for an in-depth discussion covering ways to eliminate human error and other associated risks when producing small batches of sterile GMP product for Phase 1 and 2 clinical trials.

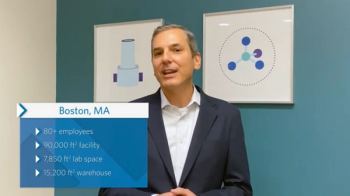

The Boston, MA facility is Catalent’s global Center of Excellence for spray dry dispersion and Dry Powder Inhaler (DPI) capsule manufacture and packaging. The site has over 20 years of experience in inhalable dry powders and Catalent is the only CDMO globally to offer end-to-end spray drying, powder encapsulation and blister packaging capabilities from development through clinical and commercial manufacturing. This video tour showcases Catalent Boston’s manufacturing operations as well as on-site analytical support services.

There continues to be a rapid expansion in the orally inhaled therapeutic pipeline, underpinned by scientific, technological, manufacturing and regulatory advances across drug products and devices. In this Q&A article, Catalent experts Carolyn Berg and Carla Vozone discuss innovations in orally inhaled drug products, in particular dry powders for inhalation.

This case study demonstrates scale-up of mRNA supply chain, increased quality standards, and global supply capabilities within record-breaking time.

For a pharmaceutical manufacturer, choosing the QMS that is right for you can be a daunting task. This guide offers a review of the obstacles most likely to hinder a quick, smooth, and effective QMS implementation.

Bachem provides superior quality APIs and meets the high industry standards for achieving successful formulation of microspheres and nanoparticles.

Industry changes, such as shorter timelines and increased product complexity, can often introduce additional risks to the sterile fill/finish process, resulting in production delays, additional costs, and safety concerns.

Eurofins BioPharma Product Testing can help eliminate human error and other associated risks when producing small batches of sterile GMP product for Phase 1 and 2 trials using our state-of-the-art Vanrx Microcell Vial Filler at our San Diego, CA, laboratory. With flexible scheduling due to small batch sizes and streamlined batch records, we can help you ensure fast delivery to the patient. Learn More about Eurofins BioPharma Product Testing’s sterile fill/finish services.

CPI, a CDMO specializing in Wurster fluid bed coating, has designed and optimized their equipment to create quality coated products.