Articles by Charles Ross & Son Labs

Tumble blenders deliver highly accurate and repeatable mixing of powders, granules and even low-viscosity slurries. In addition, this style blender enables complete discharge and easy cleaning. This bulletin presents some design considerations for maximizing mixing efficiency in a tumble blender and selecting the most suitable features for a particular application.

Consider upgrading your emulsification process to an ultra-high shear mixer to obtain finer droplet sizes and handle higher viscosity emulsions.

This white paper presents an overview of mixing technologies implemented across many of today’s highly competitive pharmaceutical and medical industries, as well as new equipment designs that are increasingly being recognized as potential solutions to prevailing mixing challenges. Mixing applications falling within the broad spectrum of mass produced pharmaceutical goods and medical devices are too many and complex to discuss in detail hence this paper will touch on a few general classifications as well as a few examples within that mixing category. Phase and viscosity are used as bases for classification.

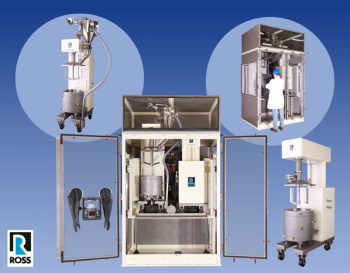

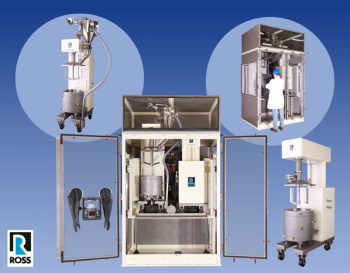

Process equipment used in the healthcare and pharmaceutical industries follow rigid specifications for accuracy, consistency and cleanliness.

Process equipment used in the healthcare and pharmaceutical industries follow rigid specifications for accuracy, consistency and cleanliness.

Process equipment used in the healthcare and pharmaceutical industries follow rigid specifications for accuracy, consistency and cleanliness.

Process equipment used in the healthcare and pharmaceutical industries follow rigid specifications for accuracy, consistency and cleanliness.

Process equipment used in the healthcare and pharmaceutical industries follow rigid specifications for accuracy, consistency and cleanliness.

The ROSS Mixing/Melting and Holding Tank System can produce highly potent and reactive materials at 350°F and up to 10 psig internal pressure.