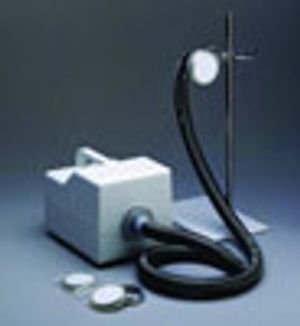

The article describes the basic principles of blow-fill-seal (BFS) technology together with the advantages it offers. Although BFS technology is an ideal process for aseptic filling of liquid pharmaceutical products there is still a risk of contaminating the product inside the filling area. This, together with regulatory requirements for the microbiological control of critical areas in pharmaceutical production, makes microbiological monitoring a necessity.