Technological advances are progressing pharmaceutical packaging to overcome the challenges of the future.

Technological advances are progressing pharmaceutical packaging to overcome the challenges of the future.

This article is focused on introducing a control chart technique using relative standard deviation (RSD) statistics (i.e., RSD chart); in other words, a coefficient of variation chart for continued process verification.

Point-of-use manufacturing may lead to a big change in the accessibility of medicines globally.

Biologics are forming a greater proportion of the development pipeline, but there are still some formulation difficulties to overcome to ensure clinical and commercial success.

Single-cell analytical technologies can deepen the understanding of cell biology and, therefore, disease mechanisms.

Automation and digitalization work together in the digital plant.

Lack of toxicity data and poor physicochemical properties must be overcome.

Demand spurs innovations in syringes and syringe fill/finish operations.

By understanding potential material change, the impact on patient safety can be understood and mitigated.

As a result of the disruptions caused by the COVID-19 pandemic, global arbitration has adapted to a ‘new normal’.

A new strategy aims to bring in legislative reforms that will impact medicinal product regulation within Europe.

Agency leaders are moving to develop a rating system to identify those drug manufacturers with more dependable production operations.

Pharma should expand on successful cell therapies in oncology by applying these development and manufacturing methods to neuronal cell therapies.

As we reach further afield in the molecular universe, we encounter new types of problems to resolve.

An SOP for electronic-records archiving is a regulatory requirement and good for business, says Siegfried Schmitt, vice president, Technical at Parexel.

Dame Deborah James’ legacy and the millions raised through her campaigning will undoubtedly be a big boost to clinical research, ultimately providing new and promising treatments for bowel cancer patients.

The AseptiQuik G DC connector is a single, sterile connection technology that can connect and disconnect tubing aseptically.

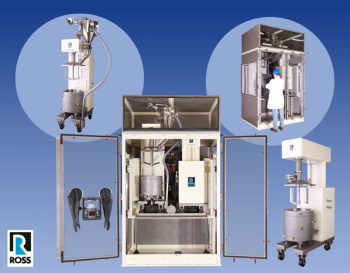

The ROSS Mixing/Melting and Holding Tank System can generate up to 10 psig internal pressure to produce potent and reactive materials.

Steriline’s Robotic Nest Filling Machine is designed to minimize human intervention in aseptic processing of injectable drugs.

The ROSS Mixing/Melting and Holding Tank System can generate up to 10 psig internal pressure to produce potent and reactive materials.

Systemic inefficiencies in the pharmaceutical industry undermine problem-solving efforts.