The expansion gives the company diversified capacity running cell production lines featuring Sartorius-brand 2000-L disposable bioreactors and now GE-brand 2000-L single-use bioreactors.

The expansion gives the company diversified capacity running cell production lines featuring Sartorius-brand 2000-L disposable bioreactors and now GE-brand 2000-L single-use bioreactors.

The company presented data on its G2 glycosylation studies at the 15th European Conference on Fungal Genetics in Rome on Feb. 19, 2020.

The company has said that all three of its operating sites in China started back up on Feb. 12 and that it is closely monitoring the outbreak.

The new facility includes six classified environment rooms with space to expand.

Contract partners must help innovators, especially smaller and virtual companies, consider manufacturability as early as possible in development. This requires focusing on technical and operational performance, as well as cost.

The need for manufacturing speed inspires contract manufacturers to explore advanced processing technologies.

The new facility, to be operated under the newly formed CDMO, The Center for Breakthrough Medicines, will be located in King of Prussia, PA, and will increase manufacturing capacity for cell and gene therapies.

The formation of the new gene therapy company stems from the progress and success of Nationwide Children’s Hospital’s clinical manufacturing and gene therapy work.

The next-generation gene editing system can be applied to the development of novel cell and gene therapies.

Achieving effective manufacturing processes and sufficient capacity remains a top priority across a diversified biologic drug pipeline.

Sartorius and the German Research Center for Artificial Intelligence have established a research laboratory for AI in the biopharmaceutical industry.

The acquisition expands Charles River’s scientific capabilities in cell therapy development.

Long a staple for quality by design and solid dosage form manufacturing, design of experiments is becoming an integral part of biopharma upstream process development.

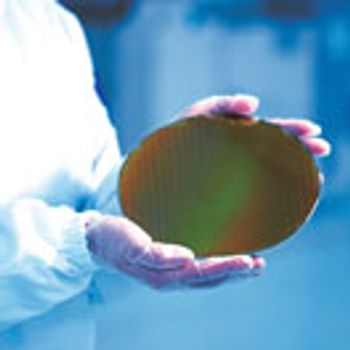

Applying lessons of raw materials’ characterization and supply-chain control from the semiconductor industry allow more rigorous control of the biopharmaceutical manufacturing process.

Fujifilm Diosynth Biotechnologies will add a new building, including gene therapy laboratories, to its facility in College Station, TX.

In batch production, efficient exception management means reducing the time required to identify, review, and resolve process exceptions. Incorporating review by exception functionality within manufacturing execution system (MES) software can streamline biopharmaceutical product release.

GE Healthcare Life Sciences will supply Akeso Pharmaceuticals with the FlexFactory platform to accelerate production of antibody drugs in the Guangzhou region.

GE Healthcare Life Sciences’ KUBio box is an integrated, flexible biomanufacturing environment for viral vector-based gene therapies.

The partners have developed a scalable, cost-effective purification process for adeno-associated viruses.

The new location is one of the world’s first digital facilities to use intensified, continuous biologics production technology.

Lonza, through its Ibex Solutions, will now cover preclinical and clinical development and manufacturing for a significant portion of Genmab’s pipeline.

Automated, electronic systems for raw materials tracking improve efficiency and prevent mistakes in biopharma manufacturing.

GSK’s expanded R&D and manufacturing facility in Upper Merion, PA houses a new analytical lab and flexible manufacturing equipment, including single-use bioreactors.

The new program, Cornerstone, integrates process development expertise and novel technology to remove development bottlenecks in the manufacture of gene therapy medicinal products.

Nephron Pharma and the University of South Carolina plan to build a sterile compounding lab at the University for research and training.