Pharmaceutical science and technology news

Pharmaceutical science and technology news

FDA initiatives aim to spur the development of more-affordable treatments and ensure safe product use.

Pharmaceutical science and technology news.

This year has been one of tremendous activity at the US Food and Drug Administration (FDA) and other government agencies involved with health care, biomedical research and national security. Scientists completed sequencing the human genome, setting the stage for a period of important new medical therapy development. Efforts to protect the nation from biological warfare created pressures to produce new vaccines and medical treatments able to counter biological, chemical and radiological attacks (see sidebar "Combating bioterrorism").

When implementing computerized systems, it is important that both purchasers and vendors ensure that each stage of the process (from planning through operation to modifying) is properly validated. This article looks at some of the issues that arise when switching from traditional document-based procedures, and at the benefits that computerized systems can bring.

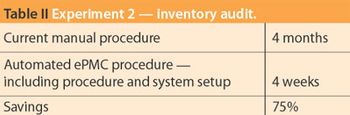

The importance of calibrating instruments used in manufacturing processes is well known, particularly for highly regulated industries such as pharmaceutical production. This article discusses software applications used to support calibration management, and the potential economic gain to be had by replacing a standalone software application with a capable enterprise system.

The Six Sigma approach would appear to be ideally suited to pharmaceutical processes, yet the industry has been very slow to adopt it. This article looks at the possible reasons for this, and suggests an alternative methodology that takes advantage of Six Sigma tools and techniques, backed by good statistical principles.

Pharmaceutical science & technology news

Pharmaceutical science and technology

With the advent of regulations such as 21 CFR Part 11 and the introduction of the electronic common technical document, it is becoming increasingly important to be able to enhance and fully utilize data management systems. Document change management is a vital tool in the construction and organization of valuable information, and can play a key role in the all-important process of getting a product to market.

Until specific audit trail requirements are available from the US Food and Drug Administration, manufacturers must define their own parameters for software system compliance and decide for themselves how to meet those requirements.

Pharmaceutical science & technology news.

Pharmaceutical science & technology news.

The aim of this study was to validate the automated clean-in-place (CIP) system installed on a capsule filling machine to determine its ability to adequately eliminate contaminants. The results obtained from the proposed cleaning validation trial showed that all the soluble tracer was removed after the washing procedure. At the end of the CIP procedure, the discharged water had the same pH, phosphate content and total organic content as the supplied water. Lack of cross-contamination in the product was also demonstrated and a recovery trial highlighted the complete elimination of the tracer from the machine.

Single-use filtration technology is becoming increasingly popular as manufacturers seek to cut costs and minimize processing times.

More than 6 years have elapsed since the US Food and Drug Administration's (FDA's) 21 CFR Part 11 regulations regarding the use of electronic records and electronic signatures came into effect.1 In February 2003, FDA issued new draft guidance concerning the scope and application of Part 11, which describes how the agency intends to interpret and enforce the requirements during its ongoing re-examination of the regulations.2 Many people in the pharmaceutical industry have welcomed this new guidance and see it as a positive development that will lead to a simplified FDA approach to Part 11 and a significant reduction in the industry's compliance burden.

Paper batch records have been used for decades to record procedures, the type and quantity of each material used, and the status of each step in the manufacturing process for both pharmaceuticals and medical devices. Although paper batch records are less complicated to implement than their electronic counterparts, and the controls required for data recording and archival are well understood, a paper batch record system is laborious to maintain and prone to human error, which increases the compliance risk. Additionally, batch records have become bulky and more time consuming to prepare and review, particularly as manufacturing operations become increasingly complicated. Advances in technology and science have created a more competitive climate in life science industries than ever before, causing the need for manufacturers to reduce costs and time-to-market, and improve their ability to satisfy the compliance requirements of US Food and Drug Administration (FDA) regulations. The use of electronic batch recording systems (EBRS) and electronic batch records (EBR) offers one solution.

Part I of this article was published in the March 2003 issue of 21 CFR Part 11: Compliance and Beyond. In this issue, Part II discusses the potential advances and changes that must be made for computer validation to remain innovative and relevant to the industry.

In an interview earlier this year (Bio-IT World, April 2003), Janet Woodcock, director of the Center for Drug Evaluation and Research (CDER), stated that "The original intent of the rule (21 CFR Part 11) was to facilitate the introduction of electronic technology to the process of the US Food and Drug Administration (FDA) submissions, as well as manufacturing and production. Part 11 was created to provide common-sense guidelines on how to do in the electronic world what was previously done on paper. During the last 5 years, however, confusion regarding what is included in the regulation and how to enforce it was impeding the introduction of new technology. The rule had created exactly the opposite of what was intended."

Manufacturers face challenges from FDA's plans to streamline the drug review and development processes aimed to spur innovation.

Pharmaceutical science & technology news.

European expert opinions regarding pharmaceutical process validation were collected and studied by performing an Internet Delphi survey. In total, 36 experts from 10 countries representing the pharmaceutical fields of industry, regulation and academia participated in the survey. The overall attitude to process validation appeared to be positive; however, a number of concerns were raised. More education, better use of prioritizing tools and increased evidence of cost-effectiveness is needed to further develop and facilitate process validation.

In December 2002, FDA notified DMV International that its pharmaceutical lactose manufacturing facility in The Netherlands had passed inspection. It was only 3 years earlier that DMV had started an ambitious programme to implement cGMP for API production conforming with ICH Q7A guidelines.

During the last few years, it has become increasingly apparent that many large pharmaceutical companies are moving their research and development operations to the US, leaving Europe with increasing numbers of smaller companies. This article briefly examines the possible motives for relocation, including the impact of regulation differences between the US and Europe.

Pharmaceutical science & technology news.