Manufacturers seek more sustainable options for temperature-controlled packaging.

Hallie Forcinio is packing editor for Pharmaceutical Technology and Pharmaceutical Technology Europe, editorhal@sbcglobal.net.

Manufacturers seek more sustainable options for temperature-controlled packaging.

Container and equipment innovations expand applications.

Drug product security requires anti-counterfeiting techniques such as authentication throughout the supply chain.

Data and software identify optimum pharmaceutical packaging choices for the required shelf-life.

New options for pharmaceutical tubes enhance functionality, sustainability, and brand identity.

Advances in intelligent technologies for pharmaceutical packaging improve online productivity, authenticate product, and boost patient adherence.

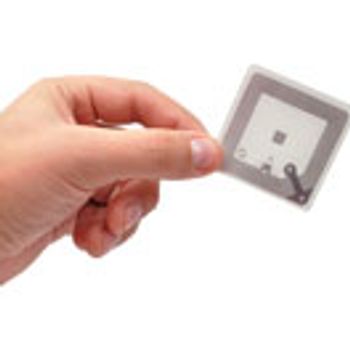

RFID, NFC, and barcodes on pharmaceutical containers enhance patient safety and adherence.

Innovations in packaging protect temperature-sensitive drugs.

Consider trends for packaging that protects temperature-sensitive drugs.

More sustainable and functional packaging protects temperature-sensitive drugs.

Labeling equipment for primary and secondary packaging and a new label printer improve speed and quality.

Pharmaceutical companies work toward a circular economy by using sustainable packaging.

Pharmaceutical companies work toward a circular economy by using sustainable packaging.

Trends affecting primary pharmaceutical packaging include the shift to more complex drug-device combination products.

Advances in fill/finish for parenteral packaging address demands for efficiency and product safety.

The Industry 4. 0 tools of augmented and virtual reality aid pharmaceutical fill/finish equipment design, training, and troubleshooting.

New machine vision systems are designed for inspecting primary and secondary packaging for defects.

Teva harmonizes its generic drug packaging brands under its corporate umbrella with a redesign.

Today’s inspection systems catch tinier flaws, manage data, and increasingly rely on artificial intelligence to further boost performance.

New testing equipment for seal integrity of pharmaceutical packaging improves accuracy and flexibility.

INTERPHEX 2019 presented solutions for ophthalmic containers, materials, and equipment for forming primary containers, child-resistant and tamper-evident (TE) cartons, and cold-chain packaging.

Contract packagers expand operations and services to accommodate growing need.

Contract packagers expand operations and services to accommodate growing need.

Exhibitors present innovations for solid doses at INTERPHEX 2019.

Serialization-ready packing equipment and services to manage data assist companies with DSCSA compliance.

At INTERPHEX 2019, MG2/MG America stages a packaging/processing summit; exhibitors offer packaging equipment innovations for parenteral products.

As demand increases, new materials and machines broaden options for blister packaging.

Active and intelligent packaging technologies benefit brand owners, caregivers, and patients.

Active and intelligent packaging technologies benefit brand owners, caregivers, and patients.

Uhlmann prepared 47 lines to meet the EU Falsified Medicines Directive deadline.