Applying a QbD approach helps address excipient variability and other quality features.

Applying a QbD approach helps address excipient variability and other quality features.

Lonza’s new complex will occupy 2000 m2 of the facility with six levels of manufacturing space and will provide room for future small-molecule technologies expansion.

DFE’s new line will offer market purity and low endotoxin excipients for use in formulation, while providing drug developers and manufacturers high-quality excipient technology and services.

Intensified and distributed manufacturing approaches create flexible, local capacity.

Topical drugs are attractive to patients, but these complex products pose challenges for formulators.

The companies will work to discover and develop RNA-targeting small-molecule therapeutics for difficult-to-address indications.

Continuus Pharmaceuticals is building the first GMP facility using integrated continuous manufacturing technology for end-to-end production of small-molecule APIs and finished dosage forms.

USP is collaborating with Phlow to build a new lab that will develop test methods and standards to facilitate broader adoption of continuous manufacturing.

Without an independent approval pathway for novel excipients, true pharmaceutical innovation could be stymied.

Various strategies to improve bioavailability are being continuously evaluated, affording greater commercial prospects for the future.

FDA moves recommended timeline for API and drug manufacturers to assess impurity risks to March 31, 2021.

The company will join the network of approved manufacturers of the lipid excipients.

The deal expands Wavelength’s drug substance manufacturing footprint and its API CDMO business.

The increased services will work in conjunction with the site’s SimpliFiH Solutions first-in-human services, which includes phase-appropriate drug substance and drug product development and manufacturing.

Nanoform and Herantis have signed a biologics proof of concept agreement for formulation proof of concept projects aimed at improving nasal drug delivery to the brain.

The importance of characterizing excipients, supply chain security, and the role of novel excipients are explored.

The CGMP manufacturing agreement will expand production of lenzilumab, a candidate for COVID-19 therapy, to support a potential emergency use authorization filing.

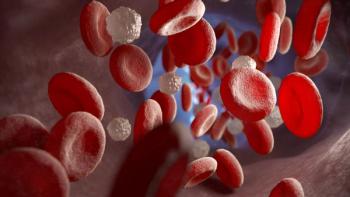

Plasma-based proteins and cell-based therapies have significant potential to address unmet medical needs.

Advanced manufacturing technologies are available, but challenges need to be addressed.

Viewpoint: Continued dialogue among pharma stakeholders is needed to achieve consensus regarding excipient composition.

Open communication and transparency coupled with technical expertise foster strong long-term manufacturing partnerships.

The collaboration will focus on up to three types of lung and gastrointestinal cancers.

Using rDNA technology to synthesize production of proteins and peptide hormones, the biotech startup has achieved synthetic production of insulin, potentially lowering insulin cost by 30%.

A newly developed polymer, DynaShield, may have the capability to ensure global access for COVID-19 treatment and prevention.

The company will expand the site to include six new containment isolators and a product development manufacturing laboratory.