Data and Artificial Intelligence

Latest News

Emerging high-tech solutions prepare to cater to industrial automation with promises of increased efficiencies, faster communications, and custom applications.

Most, if not all, pharmaceutical companies today are moving towards a paperless reporting structure. This article examines FDA's 21 CFR Part 11 regulations, which relate to technical and procedural compliance for electronic records and signatures.

Resolving the asset headache - the author explains how effective asset management can enable pharmaceutical companies to boost operational profit, increase production uptime and adhere to regulatory standards.

If an inspection reveals any shortcomings ... a manufacturer may be warned, fined, or its facility closed down until full control can be demonstrated to the satisfaction of the authorities ....

Pharmaceutical Science & Technology News

Pharmaceutical Science & Technology Innovations

pharmaceutical science and technology innovations

Pharmaceutical Science & Technology Innovations

Pharmaceutical science and technology innovations

Pharmaceutical Science & Technology News

FDA expects a firm that is subject to GxP to develop a risk evaluation of its product and to then mitigate the identified risks. Identified risks may be addressed by technical fixes that effectively eliminate the risks or reduce the likelihood of occurrence and/or severity of consequences to acceptable levels.

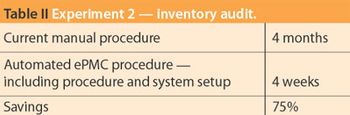

When implementing computerized systems, it is important that both purchasers and vendors ensure that each stage of the process (from planning through operation to modifying) is properly validated. This article looks at some of the issues that arise when switching from traditional document-based procedures, and at the benefits that computerized systems can bring.

The importance of calibrating instruments used in manufacturing processes is well known, particularly for highly regulated industries such as pharmaceutical production. This article discusses software applications used to support calibration management, and the potential economic gain to be had by replacing a standalone software application with a capable enterprise system.

This case study examines the benefits of introducing process information management software to a pharmaceutical pilot plant. The advantages illustrate the potential for process development and commercial manufacturing improvements that are available to the pharmaceutical industry.

With the advent of regulations such as 21 CFR Part 11 and the introduction of the electronic common technical document, it is becoming increasingly important to be able to enhance and fully utilize data management systems. Document change management is a vital tool in the construction and organization of valuable information, and can play a key role in the all-important process of getting a product to market.

Until specific audit trail requirements are available from the US Food and Drug Administration, manufacturers must define their own parameters for software system compliance and decide for themselves how to meet those requirements.

More than 6 years have elapsed since the US Food and Drug Administration's (FDA's) 21 CFR Part 11 regulations regarding the use of electronic records and electronic signatures came into effect.1 In February 2003, FDA issued new draft guidance concerning the scope and application of Part 11, which describes how the agency intends to interpret and enforce the requirements during its ongoing re-examination of the regulations.2 Many people in the pharmaceutical industry have welcomed this new guidance and see it as a positive development that will lead to a simplified FDA approach to Part 11 and a significant reduction in the industry's compliance burden.

Paper batch records have been used for decades to record procedures, the type and quantity of each material used, and the status of each step in the manufacturing process for both pharmaceuticals and medical devices. Although paper batch records are less complicated to implement than their electronic counterparts, and the controls required for data recording and archival are well understood, a paper batch record system is laborious to maintain and prone to human error, which increases the compliance risk. Additionally, batch records have become bulky and more time consuming to prepare and review, particularly as manufacturing operations become increasingly complicated. Advances in technology and science have created a more competitive climate in life science industries than ever before, causing the need for manufacturers to reduce costs and time-to-market, and improve their ability to satisfy the compliance requirements of US Food and Drug Administration (FDA) regulations. The use of electronic batch recording systems (EBRS) and electronic batch records (EBR) offers one solution.

The goal of an enterprise public-key infrastructure (PKI) is to protect information assets through electronic-based solutions that comprise hash algorithms, data encryption, digital certificates, message digests, digital signatures and audit logs. The key condition and solution critical to 21 CFR Part 11 are authentication and encryption, respectively. Authentication verifies a person's identity as well as the integrity of records. Encryption protects the privacy of records. Although most information transactions do not require this level of comprehensive digital trust, PKI is the best choice for ensuring compliance with Part 11 security requirements and consequently for ensuring the privacy of records.

Part I of this article was published in the March 2003 issue of 21 CFR Part 11: Compliance and Beyond. In this issue, Part II discusses the potential advances and changes that must be made for computer validation to remain innovative and relevant to the industry.

In an interview earlier this year (Bio-IT World, April 2003), Janet Woodcock, director of the Center for Drug Evaluation and Research (CDER), stated that "The original intent of the rule (21 CFR Part 11) was to facilitate the introduction of electronic technology to the process of the US Food and Drug Administration (FDA) submissions, as well as manufacturing and production. Part 11 was created to provide common-sense guidelines on how to do in the electronic world what was previously done on paper. During the last 5 years, however, confusion regarding what is included in the regulation and how to enforce it was impeding the introduction of new technology. The rule had created exactly the opposite of what was intended."

During the last few years, it has become increasingly apparent that many large pharmaceutical companies are moving their research and development operations to the US, leaving Europe with increasing numbers of smaller companies. This article briefly examines the possible motives for relocation, including the impact of regulation differences between the US and Europe.

This article examines the application of 21 CFR Part 11 to those areas of research and development (R&D) where compliance is not strictly required and the response of R&D equipment vendors to the rule's requirements and customer needs. The case is presented that vendors must accept that understanding and meeting Part 11 requirements is now part of their business environment.

On 20 February 2003, the US Food and Drug Administration (FDA) published a new draft guidance relating to 21 CFR Part 11. The new guidance mainly affects the compliance requirements of systems with a low risk and low impact on product quality; however, systems with a high risk and high impact on product quality, such as chromatography data systems or laboratory information management systems (LIMS), remain unaffected, as this article describes.