Advancing the use of AI to understand the whole of a disease can reveal drug development insights that lead to drug discovery breakthroughs.

Advancing the use of AI to understand the whole of a disease can reveal drug development insights that lead to drug discovery breakthroughs.

Manufacturers automate production lines and increase the use of third-party providers.

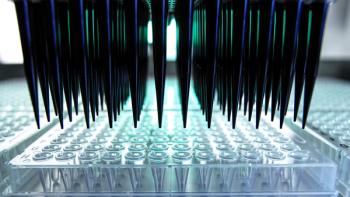

One can improve method precision and productivity by replacing one step in sample preparation with an automated approach.

Advancing digital transformation can significantly reduce R&D costs and shorten drug discovery timelines.

Replacing a step in sample preparation with an automated approach improves both method precision and productivity.

In this episode, Alivia Leon, assistant editor, speaks with Christian Dunne, director of global corporate business development, Chargepoint Technology, about current and future processing equipment trends, such as automation, cost, and sustainability.

External expertise is beneficial in helping companies select the right tools at the right stages of development to ensure success.

Automation enables intensification of downstream processes.

Automated finished product inspection has been widely adopted in the bio/pharmaceutical industry.

Integrating digital technologies into lab environments can ease workflow and enhance data capture for researchers.

Point-of-use manufacturing may lead to a big change in the accessibility of medicines globally.

Automation and digitalization work together in the digital plant.

Merck has entered into a collaboration with Agilent Technologies with the aim of filling the industry gap in PAT for downstream processing.

Lighthouse manufacturing techniques utilize technology and automation to streamline production.

Several steps need be taken to achieve lights-out, fully automated operations.

WeylChem has put a new multi-purpose custom manufacturing plant at its French site in Lamotte into operation.

Collaboration and new tools aid efforts to implement new processing technologies for small-molecule drug product manufacturing.

Smart manufacturing transforms management of tablet and capsule equipment and processes.

The acquisition and analysis of MS data can be made more efficient with the integration of modern software tools.

Digital technology streamlines the line changeover process.

Getting started with a PAT framework enables automation with digital technologies.

Automated analytical workflows require advanced technologies to manage the higher volume of data output.

Although there are challenges to be addressed, the digital transformation of equipment has begun.

Fosun Pharma and Insilico Medicine will collaborate on AI-driven drug discovery and development of product candidates targeting multiple disease targets.

Sample preparation tends to be manually labor intensive, but automating this step helps streamline the glycosylation monitoring workflow.