The global COVID-19 pandemic has highlighted the need for the pharmaceutical industry to strengthen its supply chain.

The global COVID-19 pandemic has highlighted the need for the pharmaceutical industry to strengthen its supply chain.

A network-based supply chain approach has the potential to improve resilience and performance.

US manufacturers focus on preparing capacity while vaccines and treatments for COVID-19 are being developed and tested.

Evonik opened a new facility for GMP manufacturing of bioresorbable polymers and excipients for pharmaceutical and medical applications in Birmingham, AL.

Quartic.ai and Bright Path Laboratories have agreed to develop an artificial intelligence (AI)-powered continuous manufacturing platform for APIs and other small-molecule drugs using Bright Path Labs’ continuous bioreactor and the Quartic.ai smart manufacturing technology.

CMO Evonik begins capacity expansion of APIs and intermediates at its sites in Dossenheim and Hanau Germany to increase EU supply security for drug products.

Wavelength Pharmaceuticals expanded production of APIs for certain pharmaceutical products needed to manage respiratory critical care patients in the COVID-19 pandemic.

Civica Rx plans redundant manufacturing capacity to relieve and prevent shortages of generic, sterile injectable drugs.

The agency has been tasked with coordinating efforts to mitigate shortages of medicines within Europe during the COVID-19 pandemic.

More sustainable and functional packaging protects temperature-sensitive drugs.

As COVID-19 rapidly spreads, the bio/pharma industry is committing significant efforts to fast track development of therapies.

Pharmaceutical Technology spoke with Jens Andersson, purchasing director at Cambrex Karlskoga, about the best way to ensure the security of the bio/pharmaceutical materials supply chain.

Risk assessments, audits, and good communication between sponsor and supplier are key elements of supplier oversight.

Civica Rx plans redundant manufacturing capacity to relieve and prevent shortages of generic, sterile injectable drugs.

Data and analytics company GlobalData announced that there is a strain on the global biopharma industry’s supply chain due to the ongoing outbreak of COVID-19.

Launched in 2018, the Poseidon network works to bring together pharmaceutical providers to reform the pharmaceutical logistics process.

An evaluation by USP indicates bovine heparin is a potential alternative to porcine heparin.

The company has said that all three of its operating sites in China started back up on Feb. 12 and that it is closely monitoring the outbreak.

Researching excipient grades and sources, as well as screening suppliers and materials, form the basis of programs to mitigate risk.

Vein-to-vein programs are focusing on data access and traceability.

GE Healthcare Life Sciences’ new facility for cell and gene processing supplies will be open in 2022.

Aiming to break the bottlenecks that are slowing commercialization of innovative therapies, a new $50-million center in Boston will develop both cell and viral vector products within a single facility.

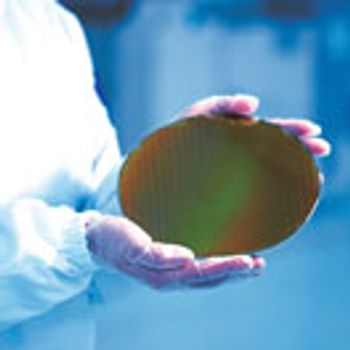

Applying lessons of raw materials’ characterization and supply-chain control from the semiconductor industry allow more rigorous control of the biopharmaceutical manufacturing process.

Communications and planning are crucial to recovering from supply, operations, and facility disruptions.

The collaboration aims to reduce “vein-to-vein” time for patients and to optimize manufacturing and supply operations.