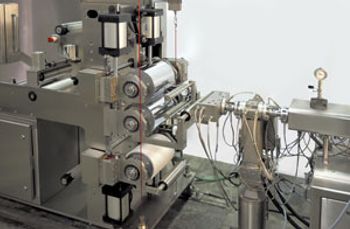

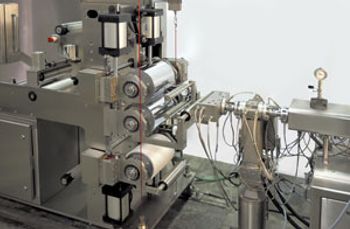

At an industry seminar hosted by Leistritz Extrusion, experts explained the use of extrusion equipment to mix polymeric excipients with APIs for solubility enhancement and for multifunctional and specialty dosage forms, including implants.

At an industry seminar hosted by Leistritz Extrusion, experts explained the use of extrusion equipment to mix polymeric excipients with APIs for solubility enhancement and for multifunctional and specialty dosage forms, including implants.

The landmark decision determined that biosimilar makers can notify manufacturers before receiving FDA approval.

Takeda will build a new production facility at its existing Grange Castle site in Ireland.

As cost pressures mount as a result of multiple biologics being developed for the same indication, manufacturers can harness process efficiencies to maintain the value of legacy products.

Follow guidelines for E&L studies of an orally inhaled and nasal drug product formulation in its delivery device.

BioVectra will open its new microbial fermentation and complex chemistry site, including the capability to handle high-potency APIs, by the end of 2017.

The pharmaceutical industry is making efforts by internally assessing, developing, and implementing semi-continuous manufacturing processes to improve manufacturing efficiencies.

The company will expand its production facilities in Carlow and Cork to meet increased global demand for its medicines and vaccines produced in Ireland.

CBER is moving forward with the development and approval of regenerative medicine advanced therapies.

Ablynx will receive EUR15 million in milestone payment following Merck’s decision to advance ALX-1141 into clinical development. The nanobody was developed by Ablynx under a 2011 collaboration between both parties.

Saneca has been granted approval to manufacture and supply multiple dosage forms to Russia.

Catalent has signed an agreement with Therachon to support preclinical and clinical development of TA-46, a novel protein being developed to treat achondroplasia.

Catalent has been working together with Lexicon to develop the drug formulation of Xermelo, which has now been approved by FDA for the treatment of carcinoid syndrome diarrhea.

Understanding the purpose of the biological indicator can guide the development of an effective sterilization process.

A multi-pronged approach to raw materials testing can help mitigate the risk of future contamination events.

The decision to use disposable bioreactors is now driven by commercial rather than technological considerations.

Manufacturing for originator molecules is restricted by regulations, but drug makers can exploit newer technologies for the manufacture of biosimilars.

Bosch’s Xelum platform is designed for continuous production of oral solid-dosage forms.

The program aims to make biosimilars for the treatment of cancer more widely available in middle- and low-income countries.

EMA and the European Commission released a biosimilars information guide for health professionals during the EC’s biosimilars conference.

Forecasts were lowered, Reuters reported, due to reduced drug approvals and increased competitive pressures.

Learn how to prevent common causes of product loss.

Robotic fill/finish systems reduce human intervention, improve flexibility, and allow more gentle handling of containers.

Advances in chemical synthesis are enabling greener, more cost-efficient processes for API manufacturing.

Catalent combines its formulation expertise, manufacturing excellence and particle size reduction technologies to provide a broad range of solutions in the development of inhalation and nasal drug products.