Aseptic connectors provide the flexibility and robustness needed for modern parenteral manufacturing operations.

Aseptic connectors provide the flexibility and robustness needed for modern parenteral manufacturing operations.

The company is cited for using unapproved visual-inspection methods for finished parenteral drugs and conducting inadequate visual inspections.

Adoption of single-use systems and more flexible systems drive innovation.

New platform technologies and polymer chemistries may facilitate self-administration, longer-term delivery, and targeted delivery of parenteral drugs.

Parenteral drug delivery offers a variety of challenges but also opportunities. The author examines recent developments in nanotechnology-based drug delivery and other advances in injection-based drug delivery.

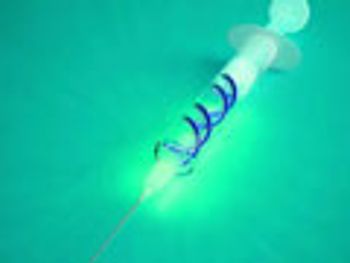

Researchers recently developed a drug-delivery system to mitigate problems associated with jet-injection drug delivery, and also improved on the design and operation of microscale actuators as a possible drug-delivery method.

Oval Medical Technologies, an autoinjector company based in Cambridge, UK, reported that a variety of highly viscous solutions have been successfully delivered through a 25-gauge thin-wall needle, in less than 7 seconds, using its innovative autoinjector. The technology provides solutions to problems in the industry for drug containment and the end user.

As an important method for improving the stability of parenterals, lyophilization is fairly well understood, but can still benefit from several advancements in the technology.

Experts describe best practices for sterility assurance in parenteral drug manufacturing. This article contains bonus online-exclusive material.

Russell Madsen, group leader of the Parenteral Drug Association (PDA) Filtration Interest Group, discusses technical and regulatory considerations in filtration for parenteral drug manufacturing

Applying quality-by-design and process analytical technology facilitates process understanding and control of various operations in lyophilization.

AAIPharma Services CEO Patrick Walsh talks about the parenterals market and the drivers for his company's recent expansion of its sterile-manufacturing capabilities.

PharmTech speaks to Ray O'Connor from the National Institute for Bioprocessing Research and Training (NIBRT) for an overview of aseptic processing.

AAIPharma Expands Parenteral Drug Capacity; Novartis Buys Dendreon Plant; and More.

Room-temperature sterilization using nitrogen dioxide gas provides benefits for sterilizing the external surfaces of single-dose, parenteral drug containers.

Plastic is finding increased use in vials and syringes as concerns about glass breakage and delamination and desire for increased functionality lead pharmaceutical companies to consider alternatives.

GSK Extends Deadline for Tender Offer to Acquire Human Genome Services; Sartorius Opens New Filter, Aseptic-Bag Production Facility in Puerto Rico; and More.

How to avoid invisible and airborne contamination.

PDA Revises Technical Report on Sterilized Products

The Parenteral Drug Association has released guidance on the detection and mitigation of 2,4,6-tribromoanisole and 2,4,6-trichloroanisole taints and odors in pharmaceutical and healthcare products.

Industry experts working with extended-release injectables discuss challenges and solutions to formulating and manufacturing these complex products.

Closed-vial technology is an alternative to traditional glass vial filling that reduces the risk of contamination for the patient, simplifies the filling process, and provides easier handling for healthcare providers.

FDA has released a final guidance describing cGMP for preparing media fills for validation of aseptic preparations for positron emission tomography drugs.

JHS Secures Four Sterile Parenteral Products Manufacturing Contracts; Samsung Biologics, Biogen Idec Establish Biosimilars Joint Venture; and More.

PDA organizes this conference to address the technical and regulatory issues related to parenteral packaging. Chemical, physical and microbiological aspects will be considered and current regulatory challenges will be discussed. Two Training Courses on Container Closure Development or Selection and Utilization of Glass Containers in Pharmaceutical Packaging will be given.