Industry awaits the final revision of USP General Chapter and the impact it will have on the evaluation of sterile product package integrity.

Industry awaits the final revision of USP General Chapter and the impact it will have on the evaluation of sterile product package integrity.

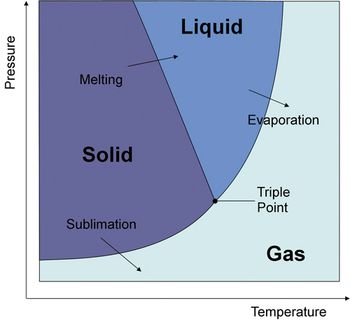

Efficient freeze-drying processes result in time and energy savings, reduced failure rates, and improved batch consistency.

A new machine is designed for inspection of prefilled syringes.

A new technical report guides bio/pharma companies in establishing a risk-based approach for prevention and management of drug shortages.

Pre-sterilized, nested syringes and vials are seeing increased use in sterile filling.

GSK Australia's Boronia site will install next-generation blow-fill-seal machinery for aseptic filling.

Grand River Aseptic Manufacturing has announced that the company executed two commercial production contracts in one day.

The parenteral manufacturing industry is taking action to address particulate contamination issues.

PDA will publish a technical report on quality risk management aspects of drug shortages in early 2015.

PDA surveys are designed to evaluate quality metrics practices at member organizations.

Innovative therapeutic approaches beyond mAbs will require new methods for future facility construction.

Representatives of contract service organizations that specialize in parenteral drug development and manufacturing describe the evolving trends.

Nitrogen dioxide can sterilize and depyrogenate an aseptic fill area in a blow-fill-seal process.

New advanced aseptic manufacturing technologies are available for filling liquid pharmaceuticals, including biologics.

Funding boosts life-sciences manufacturing in West Michigan.

Application of single-use technology in a parenteral facility for syringe filling.

Catalent's Advasept platform uses blow-fill-seal technology to aseptically manufacture, fill, and seal a polymeric primary container for injectable drugs.

The ionHP biodecontamination hydrogen peroxide-based sterilization technology is designed for use in aseptic enclosures.

Dalton Pharma completes its $2.5 million expansion in Toronto for sterile and aseptic filling capabilities.

PDA works with FDA to create pharmaceutical quality metrics.

Progress in delivery science, manufacturing technologies, and commercialization are playing critical roles in advancing the development of complex parenteral drug formulations for new drug substances having a variety of formulation challenges

Aesica expands aseptic capabilities at its Nottingham, UK site with the acquisition of new pre-filled syringes manufacturing equipment.

RABS is a flexible barrier system that maximizes product control but minimizes operator interaction when best practices are followed.

Susan Schniepp, vice-president of quality and regulatory affairs at Allergy Laboratories and co-chair of the program planning committee for the 2013 PDA/FDA Joint Regulatory Conference, discusses quality systems and related considerations in parenteral drug manufacturing.

New cartridges designed specifically for use on high-speed filling lines increase efficiency.