High performance liquid chromatography has become an efficient technique at the production scale, and simulated moving bed chromatography provides several benefits during processing.

High performance liquid chromatography has become an efficient technique at the production scale, and simulated moving bed chromatography provides several benefits during processing.

Poor processing and misguided projections lead to trashed product.

The recently published Orange Guide 2007 contains significant changes to the GMP requirement placed on pharmaceutical manufacturers, but there have been additional changes to good distribution practice that should not be overlooked.

The authors discuss how companies facing ever-evolving regulatory requirements can address and assess compliance risk in their operating practices.

Production sometimes follows the law of supply and reprimand.

The good ol' days weren't always good.

Look ahead to keep from falling behind.

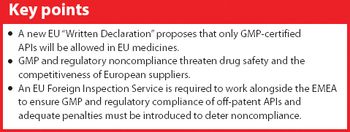

The Active Pharmaceutical Ingredients Committee (APIC) - a sector group of Conseil European des Federations de l'Industrie Chimique (CEFIC) - first voiced the need for EU GMP API legislation in 1993 to help ensure the safety of medicines. In 2000, the International Conference on Harmonisation (ICH) finalized the harmonized API GMP Guideline Q7, which became legal in the US and Japan in 2001. The EU adopted a directive in March 2004 that includes the requirement for APIs in medicines for the EU market to comply with ICH/Q7A. Member States are transposing the directive into their national law: about half of them have completed this process, seven more are well on their way to completion, while seven others are still in earlier stages of adoption.

Breaking up is easy to do.

Interphex, New York, NY (Apr. 24)-Although the second revision of 21 CFR Part 11, the Electronic Records and Signatures Rule, has not been finalized, there is some progress being made. This was the topic of a presentation given by John English, manager of computer system validation for BE&K BioPharm at today?s Interphex Pharmaceutical Manufacturing Conference and Exhibition.

Mishaps in packaging labels serve as a reminder: the recall is in the details.

This article considers the distinction among the terms qualification, validation, and verification in the context of pharmacopeial usage.A recommendation for a standardized usage of the terms validation and verification is provided,and general requirements for validation and verification activities are given.The article also emphasizes the importance of knowing when validation or verification is necessary relative to the use of a method to satisfy pharmacopeial article requirements (for which a monograph exists in the pharmacopeia) or for nonpharmacopeial use.

Missed or late calibration dates can accumulate, and even if the equipment is labelled appropriately, it can suggest poor management of resources and priorities.

Rockville, MD (Mar. 1)-Sending Warning Letters to 8 manufacturers and 12 distributors, The US Food and Drug Administration ordered a stop to the manufacture and distribution of unapproved drug products containing ergotamine tartrate.

Just because the wheels are turning doesn't mean they're going forward.

Rockville, MD (Jan. 5)-The US Food and Drug Administration issued a Warning Letter to Bell-More Laboratories following the agency?s August 2006 inspection of the company?s Hampstead pharmaceutical facility.

Rockville, MD (Feb. 1)-The US Food and Drug Administration issued a revised warning letter to Actavis Totowa, LLC, citing ?significant deviations from the current Good Manufacturing Practice regulations.?

It's what's on the outside that counts, too.

An adulteration limit of 100 ?g/25cm? (4 ?g/cm?) was proposed for pilot-plant facilities. The dynamic changes in equipment, formulation, and residue determination made implementation of a constantly changing, calculated adulteration limit impractical. A single adulteration limit was simpler to communicate and document, making compliance achievable. The limit would be used only after it was determined to be lower than a health-based evaluation and a visual-cleanliness assessment.

During the past decade, the pharmaceutical industry has increased its use of information technology (IT) in research and development, production, and commercialization of pharmaceutical products. IT systems must be operated and maintained within a compliance-oriented framework to minimize risks; maximize safety and security, integrity, accuracy, reliability of information; and maintain product quality, For IT vendors and service providers, meeting requirements for qualification and validation calls for substantial investments in terms of creating capability, expertise, and resources. The author discusses the implications, challenges, and solutions in managing IT infrastructure qualification and validation in an FDA-regulated environment, particularly at vendor sites.

The production staff was sure the lab couldn't test their way out of a paper bag.

Pharmaceuticals current good manufacturing practice (CGMP) violations accounted for just 36 of the 441 Warning Letters issued by the US Food and Drug Administration in 2006.

US District Court for the Eastern District of New York Judge Joanna Seybert's Dec. 11, 2006 Order granting a preliminary injunction in RxUSA Wholesale, et al, v. FDA, barring FDA from enforcing some drug pedigree rules.

The US Food and Drug Administration has modified its requirements for drug pedigrees accompanying wholesale pharmaceutical transactions, following a US District Court preliminary injunction barring the agency from enforcing certain provisions of the rule that was to have gone into effect on Dec. 1.

We really knew what we were doing-until we opened the column for a routine repacking.