Aseptic/Sterile Processing

Latest News

Latest Videos

More News

Manufacturers must figure out how flexible they need to be to meet the numerous new requirements of the changing therapeutic and regulatory landscapes.

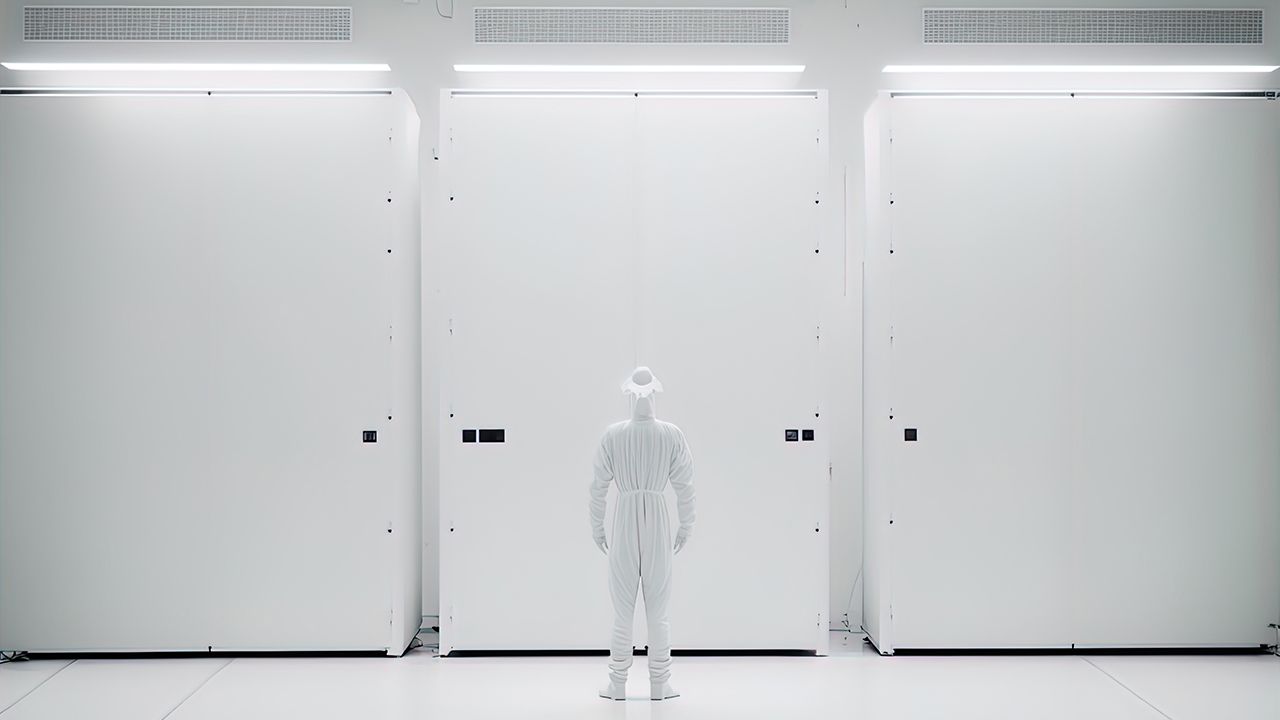

Aseptic techniques must be practiced throughout all stages of biologics production.

Contextualizing what type of flexibility is needed is paramount when considering cleanroom design.

Todd Andrews, global director of Applications and Business Development at CPC, discusses sterile aseptic connectors, flexibility in manufacturing, and more in an interview held at INTERPHEX 2023.

It’s crucial to consider the optimal handling systems for cleanroom and other lab environments.

As the therapeutic landscape grows more complex, so too must the analytical techniques for cleaning validation to ensure the utmost cleanliness is achieved.

Advances in contamination control are being to mitigate the presence of pollutants in drug products.

Address needs for integrated, automated systems and service.

Steriline will be exhibiting its vial filling and capping machine (VFCM100) under double-wall isolator for aseptic filling at CPHI 2022 in Frankfurt, Germany, on Nov. 1–3, 2022.

Recipharm’s new high speed filling line, designed for pre-filled syringes and cartridges, is expected to be operational by May 2023.

Recent technological advancements may have put cleanroom monitoring into a state of flux.

BFS technology can help maintain sterility during the biologics manufacturing process.

Various advances in contamination control are being utilized to reduce the chance pollutants contaminate a drug product.

Boehringer Ingelheim will use Virtuosi to train employees at three aseptic sites across its network.

Cleanroom monitoring may be in a state of flux after many recent technological advancements.

Validair Diamond Scientific has installed a new cleanroom for in-house testing, research, and training.

Point-of-use manufacturing may lead to a big change in the accessibility of medicines globally.

In this episode of the Drug Solutions Podcast, Meg Rivers, senior editor, discusses the importance of proper training for aseptic processing with Patrick Nieuwenhuizen, director senior consultant, PharmaLex.

Industry experts discuss the need for stricter environmental controls, whether to incorporate single-use technologies, and areas for improved automation.

PCI Pharma Services is investing $100 million in manufacturing capabilities and capacity expansion to its Bedford, NH facility.

It is vital to consider optimal cleaning and disinfection practices when operating a cleanroom.

Exhibitors display primary packaging, secondary packaging, and machine innovations at this year’s INTERPHEX.

INCOG Biopharma has completed the construction of its cleanroom production area, marking a milestone in the completion of an overall $100 million investment in a new facility.

ten23 health is expanding its sterile drug product manufacturing site at Visp, Switzerland to enlarge cold storage and visual inspections capacity and add clean rooms.

Effective cleaning and disinfection along with contamination controls are imperative when operating and utilizing a cleanroom.