Understanding the advantages and suitability of different methods to measure residual moisture content in lyophilized materials--and the respective limitations--aids in selecting the most appropriate method for testing.

Understanding the advantages and suitability of different methods to measure residual moisture content in lyophilized materials--and the respective limitations--aids in selecting the most appropriate method for testing.

Environmental monitoring, which operates below the limit of detection, is little more than a rote exercise that provides limited real value. So why does it figure so prominently in current regulatory requirements for aseptic manufacturing?

Telstar has a dedicated process analytical technology (PAT) corner at its booth to display new developments for pharmaceutical freeze drying systems and aseptic manufacturing processes.

The technology, known as Verifi, is available with the ChargePoint’s range of valves that ensure safe and contamination-free handling of API and other formulation ingredients.

Determining the right process conditions for a freeze-drying cycle requires an understanding of the effect of each step on the drug product.

Updated guidelines and new technologies aid visual inspection of parenteral products and packaging.

Airflow visualization studies, or smoke studies, confirm unidirectional airflow patterns in an aseptic processing facility.

Understanding the advantages and suitability of different methods to measure residual moisture content in lyophilized materials-and the respective limitations-aids in selecting the most appropriate method for testing.

INTERPHEX presents advances in pharmaceutical container filling, robotic handling, and serialization.

New filling and inspection machines and new containers and closures for injectable drugs will be on display at INTERPHEX 2018.

Research suggests that radiation can have a significant impact on the composition and rheology of hydroxyethyl cellulose-based medicinal gels.

Cleanroom floor and wall solutions from Sika meet rigorous standards for pharmaceutical manufacturing facilities.

The CDMO’s new blow-fill-seal machinery at its Kaysersberg site is now operational.

A previously published article presented difficulties with the revised European guidelines on sterile manufacturing. The authors included a brief summary of the comments developed on the draft document. This article expands upon that summary, outlines the authors' rationale, and highlights the most difficult aspects of the revision draft.

Revisions to chapters on glass containers and elastomeric closures were canceled following review of comments.

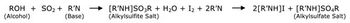

Materials used in the seals of split butterfly valves for aseptic pharmaceutical manufacturing should be chosen carefully.

The company is voluntarily recalling three lots of Labetalol Hydrochloride Injection, USP, 100 mg/20 mL Vial and one lot of Labetalol Hydrochloride Injection, USP, Novaplus because of the potential of cracked glass at the rim of the vials.

FDA sent a warning letter to Celltrion detailing CGMP violations, including poor microbial contamination control.

The NECC supervisory pharmacist at the center of the 2012 fungal meningitis outbreak was sentenced to 8 years in prison.

A different perspective on controlling fixed costs of biomanufacturing, based on know-how from other industries, provides a competitive edge, says the CEO of Samsung BioLogics.

Meissner Filtration Products has acquired PDC Aseptic Filling Systems, a supplier of aseptic filling systems and sealers, to expand Meissner's automated platform offerings.

The revised Annex 1 on sterile manufacturing includes incorrect and ambiguous statements that must be fixed before implementation.

The company will invest $139 million in sterile manufacturing technology at its facility in Ballytivnan, Sligo, Ireland to support the growth of its oncology pipeline.

PharMEDium Services, LLC voluntarily recalled some lots of product because of a lack of sterility assurance.

Sterile-molded filling assemblies from AdvantaPure are suited for single-use vial and syringe filling.