The recent heparin contamination event calls for a new approach to manage a lengthening pharmaceutical supply chain.

The recent heparin contamination event calls for a new approach to manage a lengthening pharmaceutical supply chain.

Sophisticated replication techniques have made counterfeiting and fraud a serious threat to the pharmaceutical industry.

Manufacturing facilities must be inspected by members of regulatory bodies. However… these bodies are woefully inadequate at performing the task.

Draft federal legislation that would require high-risk chemical facilities to use inherently safer technology for reducing their risk may present potential problems for custom and batch manufacturers supplying the pharmaceutical industry.

How much do you know about parallel trade? Perhaps you may have heard someone mention these words and have then switched off. In a sense, it's hardly surprising given the fact that most media coverage centres on interpretation of complex legal cases. By the time you reach the end of these types of articles, you can't work out what the mentioned companies were arguing about in the first place and on which technical details the case was judged. Yet, time after time, a legal ruling on a parallel trade issue rockets to the front pages of the pharmaceutical press and even, occasionally, the mainstream media.

Never has greater pressure been applied to pharmaceutical manufacturers. Shelf space competition for branded drugs has reached aggressive proportions and now even prescription drugs vie for pricing and delivery. Against this is a backdrop of ever-increasing downward price pressures, and a spectrum of progressively more stringent legislative and quality requirements. Finally, regional markets now demand different tamper evidence technology, anticounterfeiting measures and safeguards against interference by biological terrorists. Much of which points to the need for innovation in packaging - not just in terms of pack styles and sizes, but also cost.

Information technology is the glue that should unify a company while ironically, it enables further fragmentation. Experts talk about the successes and challenges for IT in helping a company function efficiently.

Pharmaceutical manufacturers are under increasing pressure to shorten time-to-market, produce treatments with unpredictable product lifetimes, provide greater flexibility and, at the same time, comply with ever more stringent quality, validation, stability and traceability constraints. While this is encouraging for the contract manufacturing sector, it creates the need for even greater manufacturing flexibility.

The recently published Orange Guide 2007 contains significant changes to the GMP requirement placed on pharmaceutical manufacturers, but there have been additional changes to good distribution practice that should not be overlooked.

Makers of temperature-sensitive products constantly seek to ensure proper conditions during shipping and storage.

Drug companies have come to realize that spending heavily on creating new blockbuster drugs is risky and less cost-effective ...

Driven by a rapidly ageing population and a known high consumption of pharmaceuticals, the French pharmaceutical market has always appeared buoyant.

Brussels (May 30)-The European Federation of Pharmaceutical Industries and Associations (EFPIA) called for the pan-European and industry-wide adoption of 2-D barcode technology to combat the increase in counterfeit drugs in Europe.

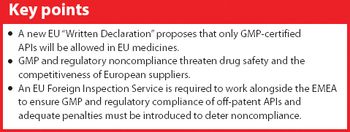

The Active Pharmaceutical Ingredients Committee (APIC) - a sector group of Conseil European des Federations de l'Industrie Chimique (CEFIC) - first voiced the need for EU GMP API legislation in 1993 to help ensure the safety of medicines. In 2000, the International Conference on Harmonisation (ICH) finalized the harmonized API GMP Guideline Q7, which became legal in the US and Japan in 2001. The EU adopted a directive in March 2004 that includes the requirement for APIs in medicines for the EU market to comply with ICH/Q7A. Member States are transposing the directive into their national law: about half of them have completed this process, seven more are well on their way to completion, while seven others are still in earlier stages of adoption.

Interphex2007, New York, NY (Apr. 26)-Counterfeit medicines are of increasing concern to the pharmaceutical industry, both because of the potential health risks to patients and because of the effects on pharmaceutical companies' businesses. While technology such as e-pedigree and radio frequency identification (RFID) represent solutions to secure the supply chain, there are challenges.

The Drug, Chemical & Associated Technologies Association (DCAT) serves as a link between sourcing and procurement professionals in the pharmaceutical industry and suppliers of pharmaceutical ingredients.

Disappointed in progress thus far, the US Food and Drug Administration wants pharmaceutical manufacturers to make a greater effort to combat counterfeit products and recommends that they "move quickly" to implement radio-frequency identification technology.

The UK Medicines and Healthcare Products Regulatory Agency (MHRA, London) has reissued its recall of a specific batch of counterfeit ?Lipitor? 20-mg tablets. MHRA, in conjunction with Pfizer (New York City, NY), first issued the recall of batch number 004405K1 in July 2005. The new recall is in response to the discovery of more packages of the counterfeit drug in the United Kingdom.

A group of researchers from Georgia Institute of Technology (Atlanta, GA) are using high-throughput ionization techniques to identify and measure the ingredients in counterfeit drugs.

Microsoft Corporation (Redmond, WA) announced the winners of the Microsoft Pharmaceuticals and Life Sciences Innovation Awards 2006 at this year?s meeting of the Drug Information Association in Philadelphia, Pennsylvania. A four-person panel of industry experts selected winners for the innovative use of Microsoft products in pharmaceutical and life sciences business processes and practices.

The US Food and Drug Administration?s Counterfeit Drug Task Force (Rockville, MD, www.fda.gov) is recommending regulatory actions and the implementation of new technologies for reducing the risk of counterfeit drugs entering the United States. The group has followed up on its original 2004 report, in which it outlined the framework for protecting the public from counterfeit medicines, and an updated 2005 report with a third document encouraging electronic pedigrees, improved traceability in the drug supply chain, and the adoption of radio-frequency identification (RFID) tools.

Interphex provided an opportunity to examine the latest pharmaceutical packaging concepts and packaging machines.

RFID and the Future of Pharmaceutical Supply Chains

Proposed Legislation to Help Fight Counterfeit Drugs