Almac introduces handling and bottling capabilities in EU and US headquarters.

Almac introduces handling and bottling capabilities in EU and US headquarters.

Risk management guides decisions in facility design and operation for highly potent drugs.

The lipid-based method provides a tool for delivery of highly potent, poorly soluble, and unstable APIs. And new in-process capsule printing and shell technologies expand softgels’ applications further.

The Fluid Air Tablet Coating System consists of a modular air atomizing manifold, liquid-delivery skid, and Batch Architect process controls.

Models and modeling software gain a foothold in solid-dosage manufacturing process design.

Crushing, fracturing, and bending tests quantify hardness.

Greater automation and the adoption of solid versus perforated pans are some recent advances.

Dynamic testing and advances in shear testing provide better insight into powder physical properties and external variables that affect powder behavior.

Crushing, fracturing, and bending tests quantify hardness.

Drug manufacturers today are increasingly challenged to find new, effective methods for the delivery of active pharmaceutical ingredients, and many are discovering that orally disintegrating technologies can help.

Podcast interview with Nick Johnson, Strategic Marketing Director for Modified Release Technologies at Catalent Pharma Solutions

The rejection by India's Supreme Court on Novartis' Glivec/Gleevec (imatinib mesylate) and other recent case law raise important issues on patent strategies for solid forms.

Solid-state chemistry is an important part of drug development, and public research is advancing the field.

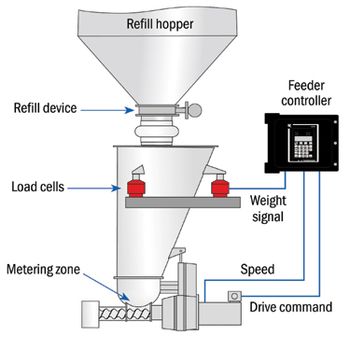

Loss-in-weight feeders provide high accuracy for batch or continuous processes.

Metrics Inc. offers Cleantaste technology, which enables polymer coating of individual drug crystals to produce particles sized 25 um to 125 um.

The trick to taste-masking in solid dosage forms is to never let the taste buds have a chance.

Industry is moving toward closed-loop control of continuous processing.

Equipment suppliers are helping the pharmaceutical industry move towards adoption of continuous tablet production.

Loss-in-weight feeders provide high accuracy for feeding powders.

Recent advances in equipment design and operation in spraying, drying, and mixing can improve the tablet-coating process.

The tableting science anti-research (TSAR) project seeks to understand why certain formulations stick to tablet tooling.

A roundtable discussion of the challenges and innovations in tablet splitting featuring Freeman Technology, Accu-Break Pharmaceuticals, and Medelpharm.

An alternative chapter has been added to the European Pharmacopoeia for dosage uniformity.